Why Ride Height Matters on Your UTV - Dive into what this is all about and what you can do to maintain your Side by Sides stance!

Understanding Suspension Sag and Maintaining Proper Factory Geometry in Your Side by Side

Ride height is not a trend, not a styling preference, and not just about clearance. It is the foundation of how your UTV handles, steers, absorbs impacts, and survives long term.

When a machine leaves the factory, its suspension geometry is engineered around a specific ride height. Control arms, steering components, shock valving, and axle angles are all designed to operate within a defined range. As that height changes over time, geometry shifts. The result is a machine that no longer behaves the way it was intended to.

Maintaining proper ride height is about protecting that original geometry.

Factory Geometry Is Engineered for a Reason

Every Side by Side platform is built with precise measurements for:

-

Camber angle

-

Caster angle

-

Toe alignment

-

Axle plunge and CV angle

-

Shock stroke position

-

Control arm operating range

These relationships are designed to keep tire contact patches consistent, steering predictable, and driveline components within safe operating limits.

When sag develops and the chassis sits lower, those angles change.

The suspension may now sit deeper into its travel at rest. Control arms rotate upward. CV joints operate at steeper angles. Shock shafts run in a different part of their stroke. None of that is catastrophic overnight, but over time it accelerates wear and reduces performance.

What Happens When Ride Height Drops

As springs fatigue and components wear, sag increases gradually. Many riders do not notice the change until handling begins to feel off.

Common long-term effects of reduced ride height:

-

Increased body roll in corners

-

More frequent bottoming

-

Reduced high-speed stability

-

Premature CV joint wear

-

Uneven tire wear

-

Added stress on ball joints and bushings

A SXS that sits even an inch lower than intended can feel completely different at speed. Steering becomes less precise. The chassis feels heavier. The suspension may feel harsh because it has less upward travel available before hitting bump stops.

Ride height is directly tied to usable suspension travel. When the machine starts too low, it runs out of travel sooner.

Suspension Sag Is Inevitable, But It Should Be Managed

All springs settle over time. That is normal. The key is recognizing when normal settling becomes excessive sag.

Contributing factors include:

Added Weight

Many modern UTV builds include:

-

Steel bumpers

-

Winches

-

Roofs and windshields

-

Spare tire carriers

-

Bed racks

-

Audio systems

These accessories improve function, but they add significant weight. Factory spring rates are rarely designed for heavily accessorized machines.

Riding Style

Aggressive riding accelerates suspension wear. Hard hits, high-speed desert sections, and loaded trail riding all increase stress on springs and shock internals.

Shock Degradation

Over time, shock oil breaks down and seals wear. Damping performance declines. Even if spring rate is still acceptable, weakened damping allows excessive movement that changes how the chassis settles.

Geometry Impacts More Than Handling

Proper ride height protects more than just comfort and cornering feel.

Driveline Longevity

CV axles are designed to operate within a specific angle range. When ride height drops, those angles increase at ride height, not just at full droop. That constant stress shortens component life.

Steering Integrity

As control arms rotate upward from sag, steering geometry shifts. Bump steer can increase. The steering rack works harder. Long-term wear accelerates.

Tire Performance

Tire contact patches depend on proper camber. Excessive sag alters camber curves, leading to uneven wear and reduced traction under load.

Maintaining geometry is about keeping all these systems working together in harmony.

Supporting Ride Height Over Time

Correcting sag is not about lifting a machine higher than stock. It is about restoring proper support so the chassis sits where it was designed to.

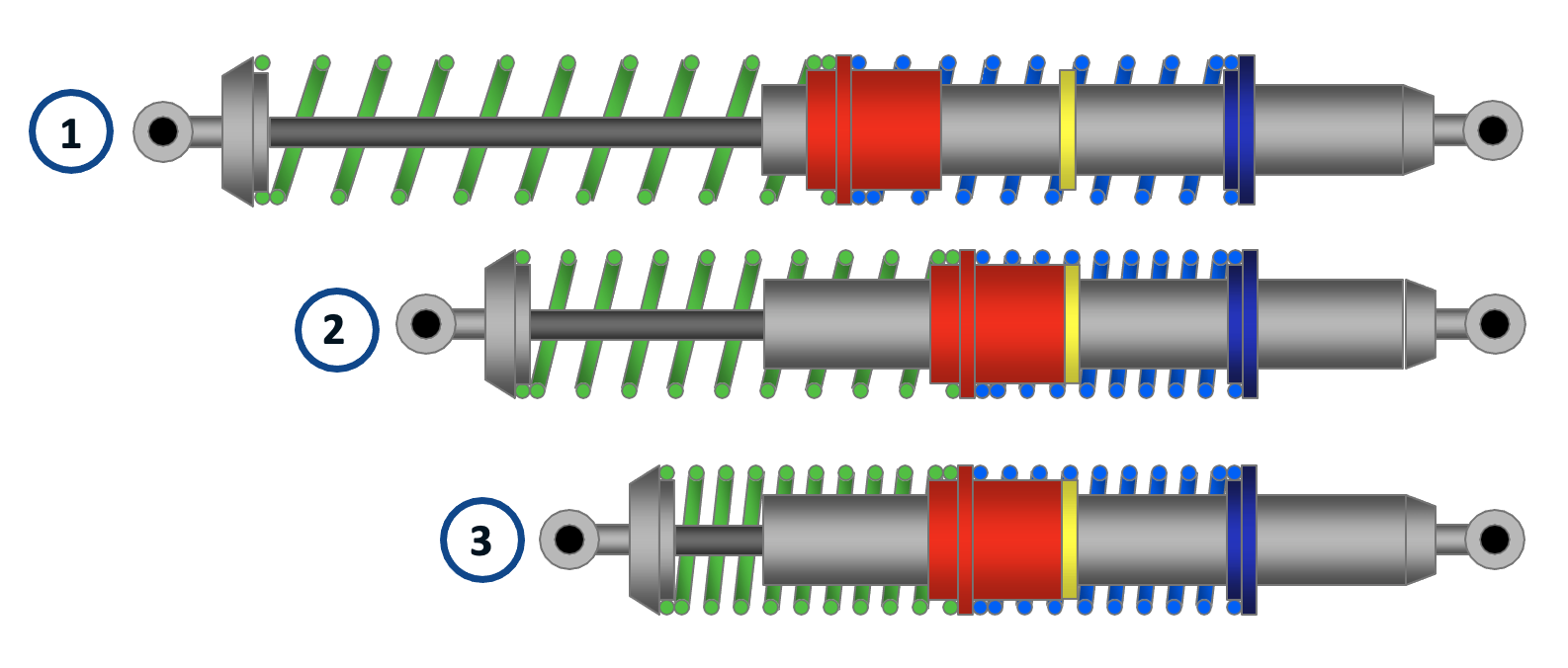

Dual Rate Spring Kits

Benefits include:

-

Improved load support for accessorized machines

-

Better resistance to bottoming

-

Restored ride height without harshness

-

More consistent suspension balance

For many UTV owners, dual rate kits are enough to bring the chassis back into its intended operating range.

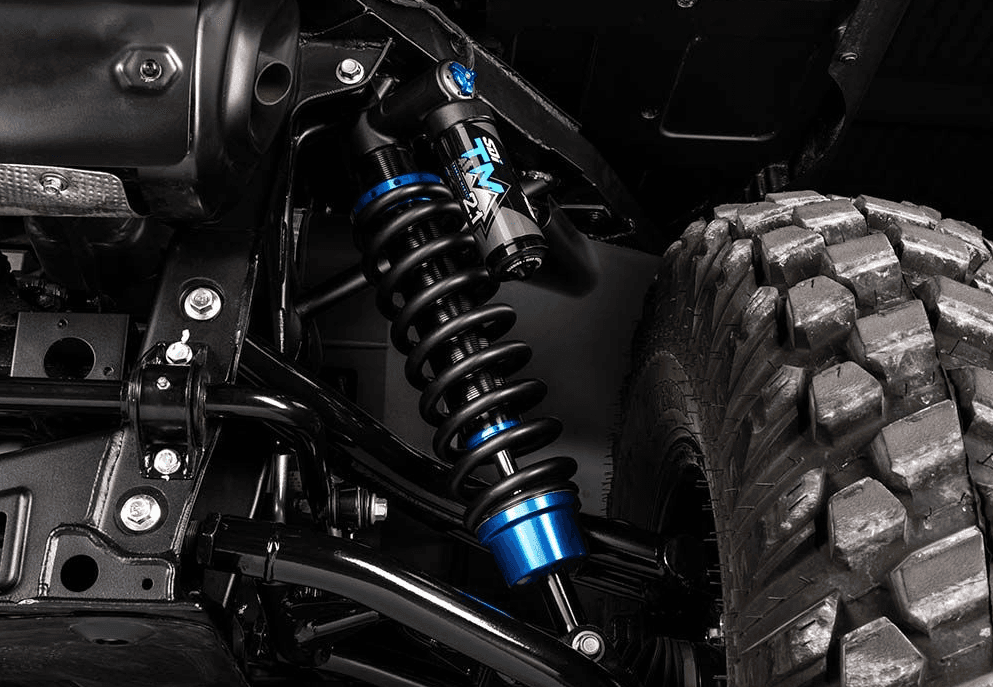

Premium Shock Systems for Long-Term Control

When damping performance is compromised or riding demands increase, upgraded shocks offer stronger internal components and improved control.

FOX Performance Shocks

ELKA Suspension

ELKA Suspension focuses heavily on tunability and rider-specific setup. That philosophy plays directly into maintaining proper ride height and suspension balance over time.

One of the most overlooked elements of geometry preservation is matching spring rate and damping to the actual weight and use of the vehicle. Many machines leave the factory with general-purpose settings designed to accommodate a wide range of riders.

ELKA systems are often configured based on:

-

Rider weight

-

Passenger load

-

Accessory weight

-

Primary riding terrain

-

Riding style

That level of customization allows the suspension to sit in the correct part of its travel at rest and remain controlled through impacts.

Key features often include:

-

Multi-stage compression adjustment

-

Adjustable rebound circuits

-

High-quality internal valving

-

Multiple spring rate options

-

Serviceable, rebuildable construction

When a UTV carries added bumpers, racks, and cargo, factory spring and damping combinations may no longer provide sufficient support. ELKA’s ability to match spring rates and damping curves more precisely helps bring the machine back into proper operating range.

Maintaining factory geometry does not always mean staying with factory components. Sometimes it means restoring the intended suspension position with components better suited to the machine’s current configuration.

SDI Suspension

SDI Suspension has focused specifically on modern UTV applications, many of which are heavier and more powerful than earlier platforms.

As machines grow in size and capability, suspension demands increase. Larger engines, stronger frames, and heavier accessories all add stress to spring and damping systems. Maintaining ride height under these conditions requires shock systems designed with sufficient oil capacity, durable internal components, and appropriate spring support.

SDI shock systems often emphasize:

-

Increased oil volume for better thermal stability

-

Stronger shaft construction

-

Application-specific valving

-

Balanced spring rate pairing

-

Serviceable design for long-term maintenance

Thermal stability plays a major role in geometry consistency. When shock oil overheats and damping weakens, suspension movement becomes less controlled. Over rough terrain, that can cause the machine to ride lower than intended for extended periods, effectively shifting geometry while in motion.

By maintaining damping performance over time and under load, SDI systems help preserve the relationship between control arms, axles, and steering components. That protection of geometry translates to improved driveline longevity and more predictable handling.

For riders who combine trail work, rocky terrain, and moderate speed sections, consistent damping and proper spring support are key to keeping the chassis balanced season after season.

Why Shock Quality Directly Impacts Ride Height

It is easy to think of ride height as purely a spring issue. In reality, springs and shocks work together to determine how the chassis sits and how it behaves under load.

Springs establish static height.

Shocks control dynamic height.

When damping is weak or inconsistent, the machine may temporarily ride lower through repeated impacts or heavy terrain. That constant cycling at lower ride positions increases wear and shifts geometry throughout the ride.

Premium suspension systems from FOX, ELKA, and SDI Suspension are designed not just for performance, but for consistency. Consistency is what protects factory geometry over the long term.

Maintaining proper ride height is ultimately about preserving the engineered relationships between every moving component in your UTV. Strong springs and durable shock systems ensure those relationships stay intact well beyond the first season of riding.

The Long-Term Perspective

Ride height does not change dramatically overnight. It shifts gradually. That gradual shift makes it easy to ignore.

But over seasons of riding, sag compounds:

-

Geometry drifts further from spec

-

Components wear faster

-

Handling degrades

-

Maintenance costs increase

Addressing suspension support early keeps the machine operating inside its intended window. It preserves factory geometry and protects the investment made in the vehicle.

Ride height is not about building a taller machine. It is about keeping your UTV operating where its engineers intended. Proper geometry supports predictable handling, longer component life, and balanced suspension performance.

As springs settle and shocks wear, restoring support with dual rate spring kits or premium shock systems from FOX, ELKA, or SDI Suspension helps bring the chassis back into alignment with its original design.

Maintaining ride height is not cosmetic. It is foundational to how a machine drives, handles, and holds up over time.